Part 7 - Detection of Lactobacillus, Diastaticus, Pediococcus, Pectinatus, Megasphaera, ... in beer: How to set up a microbiology Lab?

Setting up a microbiology entity within your laboratory

Your craft brewery is up and running, and demand is starting to grow. How do you ensure the product you are selling remains consistent in taste and quality as production increases? In addition to the physico-chemical parameters that you will be probably already monitoring in your quality control laboratory, setting up a brewery microbiology quality control capability in your laboratory is critical in answering these questions.

Getting Started

So the biggest uncertainty any brewery (whatever the size), may have is where to begin. Initial key decisions need to address :

- The goal for your microbiology laboratory

- Identify the staffing needed to operate the laboratory

- Your budget for installing a microbiology laboratory.

Whether you are building your first lab or expanding your existing laboratory, every brewery should plan for these few critical laboratory functions:

Yeast management

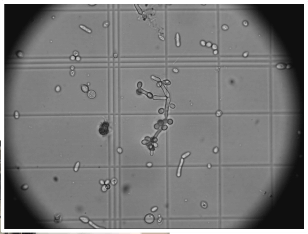

Yeast cell concentration and viability measurements are recommended for determining pitch rates and understanding yeast health during fermentation. Essentially this is just using a microscope (capable of 100 x and 400 x magnification), a hemocytometer with a Neubauer counting grid and some viability stain to view your yeast, perform cell counts for pitching rate calculations, and obtain viability data. Doing this routinely will help improve the consistency of your fermentations.

Yeast cell concentration and viability measurements are recommended for determining pitch rates and understanding yeast health during fermentation. Essentially this is just using a microscope (capable of 100 x and 400 x magnification), a hemocytometer with a Neubauer counting grid and some viability stain to view your yeast, perform cell counts for pitching rate calculations, and obtain viability data. Doing this routinely will help improve the consistency of your fermentations.

Microbiological control

Often, the quickest and easiest way to start a brewery micro laboratory is to monitor for Lactic Acid Bacteria (Lactobacillus and Pediococcus) – the two most common brewery spoilage micro-organisms. Lately, the issue of Saccharomyces var Diastaticus is also of interest to brewers as it can cause over-attenuation and gushing of kegs, bottles and cans.

Detecting micro-organisms can be done in different ways:

Traditional microbiology

As the name suggests, this fundamental technique is based on the capacity of the microorganisms to grow which often varies from 2-4 days for bacteria and 5-10 days for yeasts. To be performed correctly, this requires that the technician has been appropriately trained in basic microbiology methods to ensure the sample is correctly handled to avoid cross contamination, the culture media (whether it be ready-to-use or is made from a dehydrated format) requirements in terms of handling and preservation and quality control are respected and of course that the interpretation of the results is correct and meaningful with regards to what the brewer and/or quality control manager need to know. To grow a colony is one thing, to understand its relevance to beer production and quality is a different thing altogether (despite what certain “easy to use solutions” claim!!)

- Reconstitution of culture media /aseptic plating techniques / quality control strain propagation / Staining techniques (e.g. gram staining) and Identification techniques

Regardless of the traditional microbiology technique, some basic materials are required

- Bunsen burner / propane burner

- Incubator

- (CO2 generator for anaerobic incubation)

Spread Plate method:

- Sterile culture media plate/tube + sterile solid media

- Sterile graduated 1ml pipette + L-shaped glass rod or Microbiological loop

Membrane Filtration method:

- Manifold (including filtration cups)

- Vacuum pump

- Membrane filter (0.45µm pore size)

Need for equipment for identification of isolated microbes

- Capability for gram staining (slides, gram stain set of tests, microscope)

- Capability to perform basic orientation tests (e.g. catalase test)

- Capability to perform standard chemical and metabolic tests (e.g. sugar fermentation tests)

PCR analysis

PCR Analysis (Polymerase Chain Reaction) is a modern technique that analyses a segment of the target micro-organism’s DNA in order to detect its presence. During PCR amplification, the DNA of interest is copied repeatedly until there is enough of it for analysis and detection. Over the past 5 years, this technique has been simplified to such a degree that it is now regularly employed in brewery laboratories without requiring specialist microbiological training or the sterile room conditions that were previously necessary to avoid cross contamination. The good news is that PCR gives a result within hours, is very specific and sensitive and generally depending on the system, very little operator hands on time.

Equipment needs:

- Centrifuge

- Thermocycleur

- Pipettes + pipette tips

Fermentation control, analysis and tracking

A critical piece of any brewery quality control program. Aside from temperature, one of the most important aspects of a successful fermentation is dissolved oxygen (DO). Yeast requires oxygen to form the lipids they need to grow and function optimally. Being able to provide adequate wort oxygenation is, however, a bit of a challenge. Dissolving oxygen into liquid is very dependent on factors that are not static, such as temperature and density of the wort, as well as head pressure on the tank. Oxygen also comes out of solution quite easily, so oxygenating at the right time and place in-line is very important.

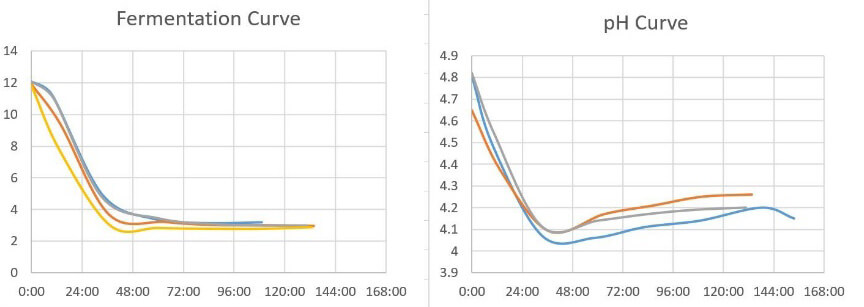

Once your fermentation is under control, you’ll want to make sure you are tracking fermentation performance to allow you to identify issues early and trouble-shoot. Much of this involves simple tracking and record-keeping for core beers of key matrices (e.g. gravity and pH) and being able to identify deviations to normal yeast behaviour. There are software programs out there that help you.

An archive for monitoring microbial contamination

Often overlooked, but this simple action will enable a brewer to monitor shelf stability of packaged beer. Ideally, 2 spaces in the brewery should be set aside, one at room temperature and one in a refrigerator. In addition to microbial contamination, these samples can also be used for other tests such as pH, CO2 and changes in the flavour profile.

It is advised to archive 6-10 bottles from every batch. Beer archiving is used to define and improve shelf life and to predict or navigate any issues that may present themselves in the market.

Key Points

• It is important form the outset to establish your goals for your microbiology entity in the laboratory

• There is a need to have a dedicated space, appropriately trained person(s) and a budget to make it happen.

• 2 main microbiology activities

- Yeast management

- Microbial detection

• Investment in the correct equipment according to what microbial testing to be performed is essential

• Microbial Quality Control : 2 technologies to be considered

- Traditional microbiology

- PCR rapid microbiology

• Important to have a dedicated space set aside for archiving bottles from different production batches during the duration of the shelf life for quality assurance purposes